SENZA PEM Hydrogen Generator

Max Hydrogen Purity: 99.995%+

Small Size

No Corrosion

High Efficiency

Just Need Pure Water

SENZA

PEM Hydrogen Generator

Max Hydrogen Purity: 99.995%+

Small Size

No Corrosion

High Efficiency

Just Need Pure Water

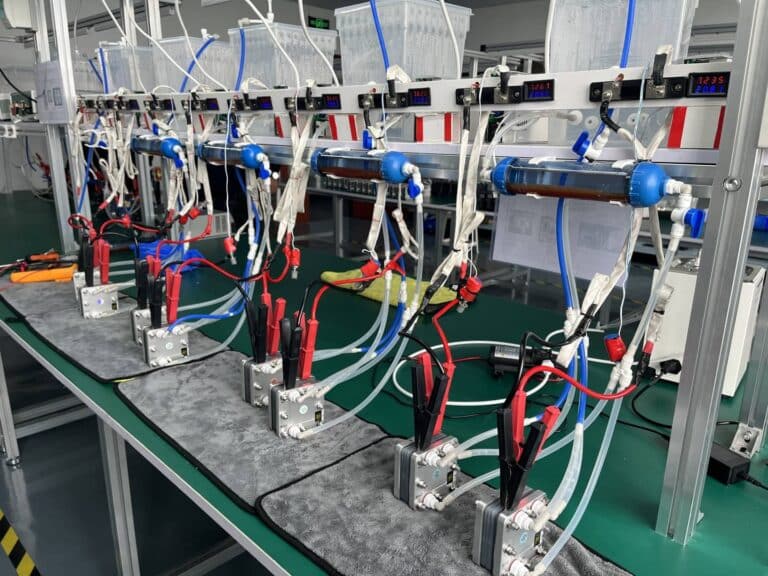

We offer two different PEM electrolyzer options

Single PEM Hydrogen Generator

In this option, we provide the electrolyzer and all its components. This is suitable for clients with limited space or those who need personalized customization.

Included Components and Accessories

Below is a list of all components and accessories included with your purchase. Each item has been carefully tested to ensure efficient and reliable performance for seamless operation.

In The Box

PEM Hydrogen Generator

Power Supply

Water Tank

Water Gas Separator Bottle

Water Pump

Installation Toolkit

All In One PEM Hydrogen Generator

About PEM Hydrogen Generator

Unlike alkaline water electrolysis hydrogen production, PEM water electrolysis hydrogen production uses a perfluorosulfonic acid proton exchange membrane with good chemical stability, proton conductivity and gas separation as a solid electrolyte instead of the asbestos membrane, which can effectively prevent electron transfer and improve Electrolyzer safety.The difference between PEM and alkaline electrolyzers

The main components of the PEM water electrolyzer are proton exchange membrane, cathode and anode catalyst layers, cathode and anode gas diffusion layers, cathode and anode end plates, etc., from inside to outside. Among them, the diffusion layer, catalytic layer and proton exchange membrane constitute the membrane electrode, which is the main place for material transport and electrochemical reaction in the entire water electrolyzer. Therefore, the characteristics and structure of the membrane electrode directly affect the performance and life of the PEM water electrolyzer.

PEM Electrolyzer : How it works

The accelerated development of renewable energy makes large-scale renewable energy consumption a major problem. Power-to-Gas (P2G) converts renewable energy power generation into hydrogen, which can improve the flexibility of the power system and is becoming an important direction for the development and application of renewable energy. PEM water electrolysis hydrogen production technology has the advantage of rapid start and stop, can match the volatility of renewable energy power generation, and gradually become the mainstream technology of P2G hydrogen production.

-1024x665.jpg.webp)

Why SENZA

Your Trusted Hydrogen Generator Manufacturer For One-stop Hydrogen System Assembly

High-mix, Low-Volume

We welcome high-volume products, but we extensively support low-volume products.

Best Value

Manufacturer Direct Pricing.

Technical Support

We welcome high-volume products, but we extensively support low-volume products.

Customised services

We offer a specialised and customised service for each customer.

R&D Team

The SENZA R & D team consists of senior automotive engineers, hydrogen energy technology experts, and technology installation engineers. It has 8 years of experience in hydrogen energy research and development and application.

Michael Wu, chief technical engineer, graduated from Sun Yat -sen University in transportation engineering. He has been engaged in engine R & D tests at Dongfeng Nissan Passenger Car Technology Center and GAC Research Institute, and is responsible for the engine R & D test project of the entire car series. Since the graduate period, Michael has been studying the characteristics of the addition of hydrogen in fuel engines. Deliven the application of hydrogen energy to fuel vehicles. Therefore, it plays a role in saving fuel consumption, increasing power, and reducing exhaust emissions.

FAQ

What Is A Hydrogen Generator ?

Hydrogen Generator : Hydrogen production by electrolysis of water is to dissociate water molecules into hydrogen and oxygen through an electrochemical process under the action of direct current, which are separated at the cathode and anode, respectively. According to the different diaphragms, it can be divided into alkaline hydrogen generator , proton exchange membrane water hydrogen generator(PEM), and solid oxide water hydrogen generator.The differences between these techniques can be seen in this article : What Is Hydrogen Electrolyzer

How Does A Hydrogen Generator Work ?

1.Alkaline Electrolysis: Alkaline hydrogen generator technology uses KOH and NaOH aqueous solution as the electrolyte, such as using asbestos cloth as the diaphragm. Under the action of direct current, the water is electrolyzed to generate hydrogen and oxygen.

2.PEM Electrolysis : Since there are still many problems in alkaline electrolysis that need to be improved, the rapid development of solid polymer electrolyte (SPE) water electrolysis technology has been promoted. The first practical SPE is a proton exchange membrane (PEM), also called PEM hydrogen generator. The asbestos membrane is replaced by a proton exchange membrane, which conducts protons and isolates the gas on both sides of the electrode. This avoids the disadvantages of using vital alkaline liquid electrolytes in alkaline electrolyzers. At the same time, the PEM water electrolysis cell adopts a zero-gap structure. As a result, the volume of the electrolytic cell is more compact and streamlined, reducing the electrolytic cell’s ohmic resistance and dramatically improving the electrolytic cell’s overall performance. The current operating density of PEM hydrogen genrator is usually higher than 1 A/cm2, which is at least four times that of alkaline water electrolytic cells. It is recognized as one of the most promising electrolytic hydrogen production technologies in the field of hydrogen production.About Hydrogen Production From Electrolysis.

What Is A Hydrogen Generator Used For ?

1.For energy storage: Used to store surplus electricity from solar and wind energy. Because the electricity generated by solar and wind energy is unstable, it is not suitable for direct integration into the grid. In addition, the price of large batteries is very high. Using excess electricity to generate hydrogen storage is a better solution, and hydrogen fuel cells, which convert hydrogen directly into electricity, are also highly efficient.

2.For car kit: Use the excess power of the car to generate HHO from the hydrogen generator and then deliver the generated HHO to the engine air intake to improve the combustion efficiency of traditional fuel.

3.For Medical: Hydrogen inhalation can be used to treat some related diseases. Because hydrogen is an antioxidant gas, it can affect human health. HHO is also known as Brown Gas.

Oxygen Not Included How To Use Hydrogen Generator ?

1.PEM hydrogen generator produce hydrogen at the cathode and oxygen at the anode. Just connect the hose to the corresponding output hole.However, you need to pay attention to the direct output of the gas will carry water vapor.

2.Alkaline Hydrogen generators are difficult to separate unless you only have one layer of stainless steel. Otherwise you need some other way to separate.